Labels

Many of our tools are used for die-cutting self-adhesive labels, which are part of our everyday life. They can be found, for example, on products in the supermarket, electrical devices in the home, pharmaceuticals in hospitals, packages in logistics centres or folders in offices. Our tools, which are individually manufactured to customer specifications, are accordingly wide-ranging.

Variations and functions

Labels are information carriers, they provide information about content, price, origin, manufacturer, risks etc. Furthermore, brands present themselves through the appearance of the label: shape, design and material make the difference at the "point of sale". Meanwhile, there are countless variations with the widest range of applications:

- Blank labels for variable printing (e.g. logistics/transport, price and weight labelling, tickets)

- Labels for product identification and advertising (e.g. for consumer goods and industrial products, brand advertising, special offers)

- Labels with special functions (e.g. multi-layer labels, piggyback labels, RFID labels, security labels, stamps)

Label production

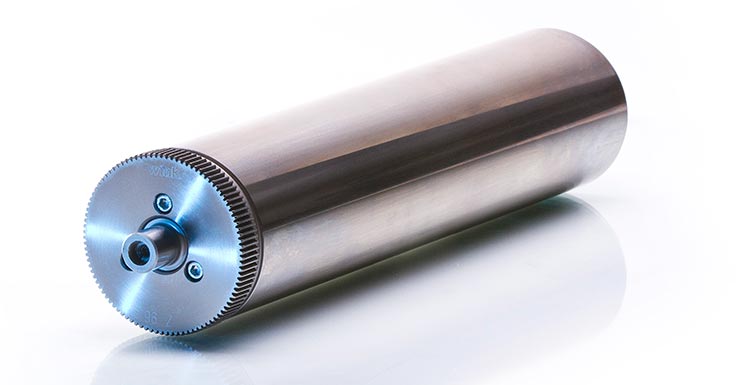

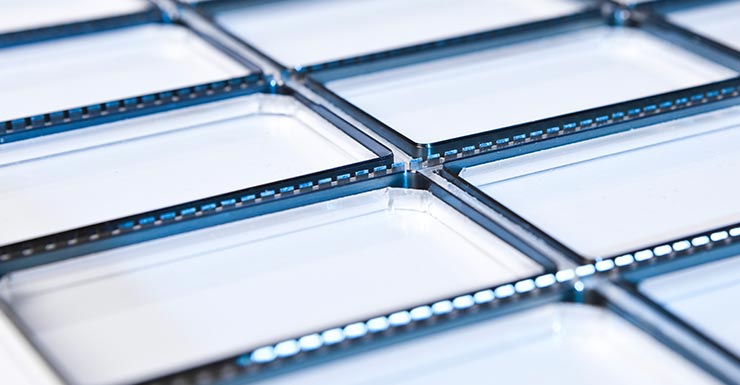

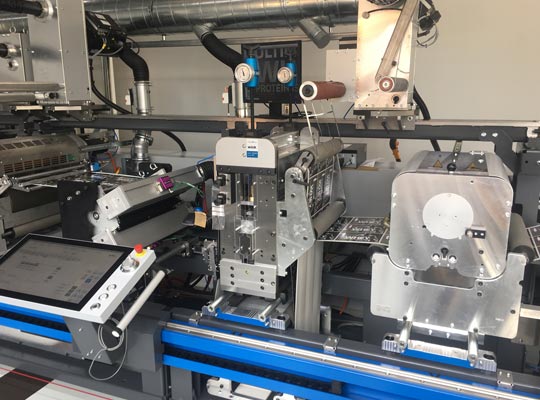

Adhesive labels are usually produced from roll-to-roll in narrow web printing. The most commonly tools used are flexible dies which are mounted on magnetic cylinders. Solid dies are also used for some rotary applications, whereas steel rule dies are used in the traditional stamping process. After die-cutting, the stripped face material is disposed of while the labels remain on the liner and are rolled up. The labels are now ready for "dispensing", the mechanical application to the end product.

Die-cutting with pinpoint accuracy

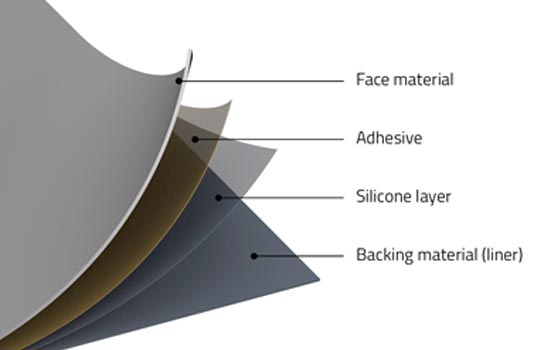

Adhesive labels made of plastic or paper have a multi-layer structure: The (printed) face material is bonded to a backing material (liner) by an adhesive layer. The art of die-cutting is to cut through the face material without damaging the siliconized liner. One micron can decide whether the labels can be processed perfectly - correspondingly high standards apply to the precision of our tools.

The right contact

Would you like to request an offer or place an order? Do you have general or technical questions? Our friendly and competent team will answer all your questions about our products and our service.