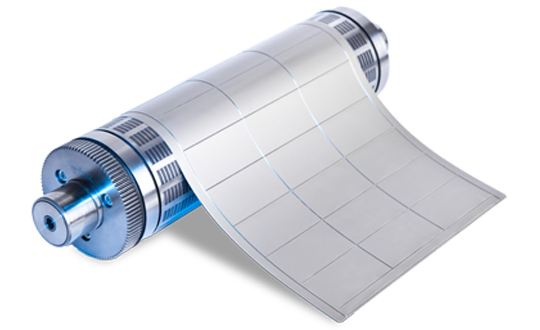

SuperCut flexible dies for labels

Our high quality SuperCut flexible dies are produced using state-of-the-art CNC technology. We guarantee minimum tolerances, maximum durability and therefore optimum cost-effectiveness.

Efficient & versatile

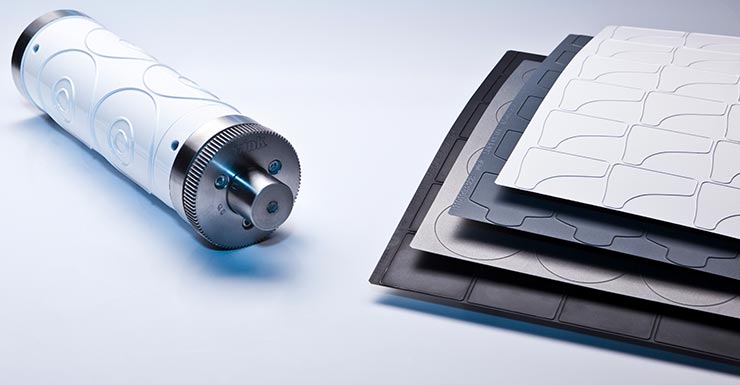

Our flexible dies can be used both flat (on magnetic foundations) and rotary (on magnetic cylinders). The different applications can also be combined in one tool if required:

- Kiss-cutting

- Through-cutting

- Creasing

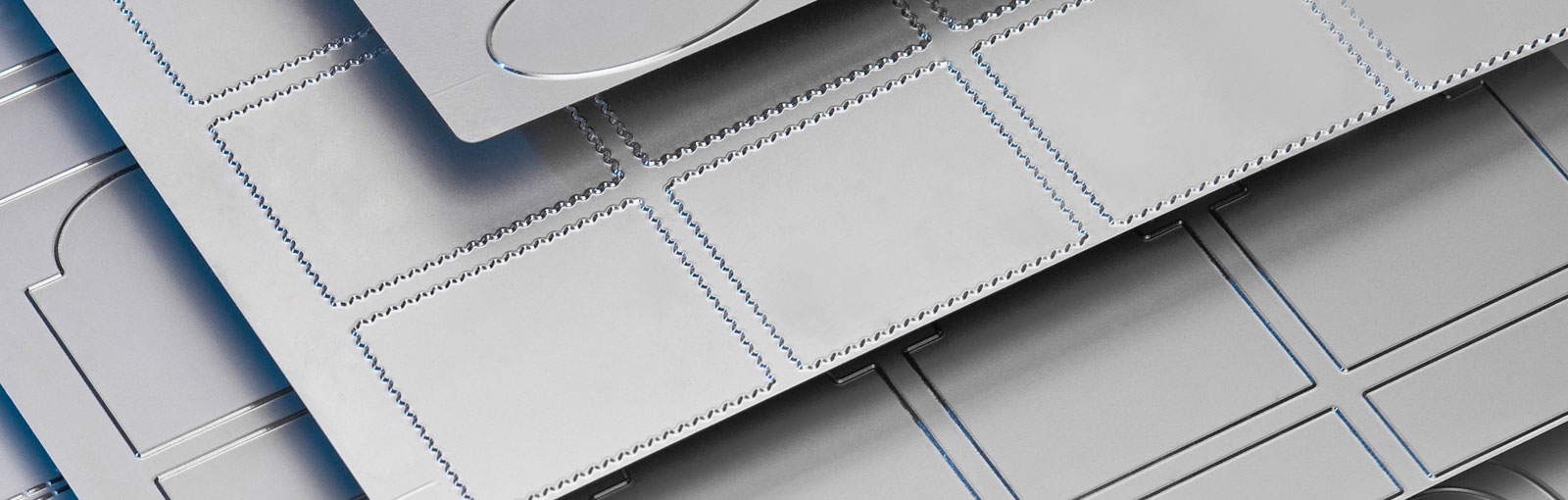

- Perforations

- Micro-perforations

Fast shipping

Maximum precision

Perfect die-cutting results

long running life

Finishings for maximum efficiency

Cutting angle & material

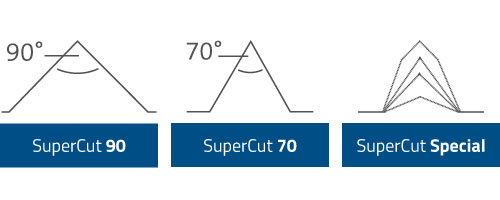

Wink offers three cutting angle types for common and special materials:

- SuperCut 90 for standard adhesive papers, thermal papers

- SuperCut 70 for films like PE 85, PP, PET; also paper materials

- SuperCut Special for special films and other difficult to die-cut materials

Materials

The base materials in the die-cutting process can cause great challenges for label manufacturers. There are countless types of label materials that differ not only in terms of material, but also in thickness and composition. In order to guarantee you perfect punching results, we work closely with the major material suppliers. To this end, we regularly test new materials in our laboratory with our own converting machine. Results and samples are carefully recorded and archived to provide you with advice and support even for the most complex applications.

Maximum performance

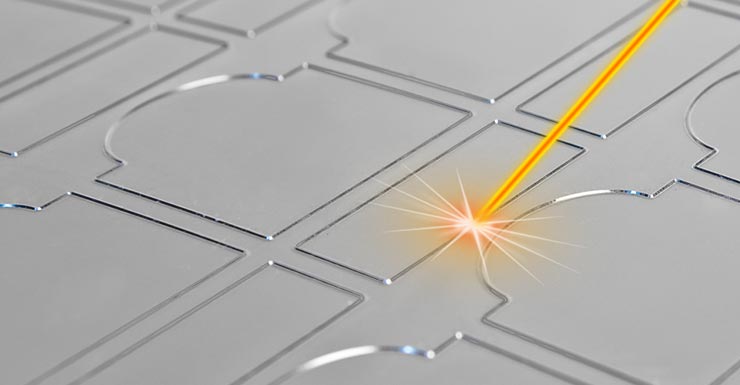

In the basic version, our SuperCut flexible dies already impress with very high performance. For certain applications, however, it makes sense to further increase the tool life by applying special hardening treatments, such as laser hardening or MCR coating. There are also materials that can be converted more efficiently with special non-stick coatings on the die-cutting tool.

- Tolerance: ± 0.002 mm

- Die height: 0.32 - 1.50 mm

- Cutting angle: 30 - 110° (depending on material)

- Versions: SuperCut 70, SuperCut 90, SuperCut Special

- Adhesive papers and thermal papers

- PE, PP, PET, PVC, Tyvek, etc.

- thin cardboard

- Sandwich material / multi-layer materials

Rotary or flat usage:

- Kiss-cutting

- Cutting-through

- Creasing

- Perforations

- Micro-perforations

- Rust protection (included)

- Laser hardening (optional)

- Non-Stick coating (optional)

The right contact

Would you like to request an offer or place an order? Do you have general or technical questions? Our friendly and competent team will answer all your questions about our products and our service.