It's not a trick,

it's Non-Stick.

Increase your efficiency and reduce your costs - enjoy smooth and clean converting jobs with our non-stick coatings for rotary dies.

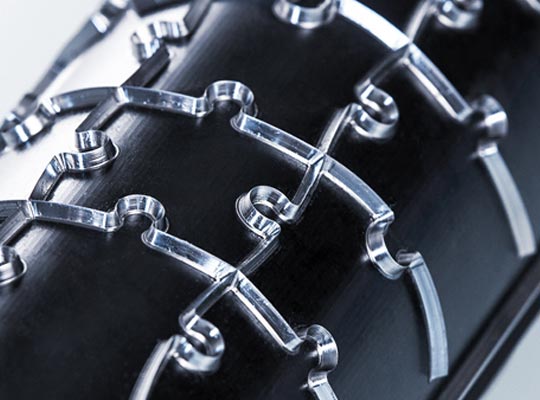

Non-stick coatings for rotary dies

Non-stick coatings for rotary dies are special surface treatments to reduce the adhesion of materials during the converting process. The coatings are usually made of Teflon, silicone or similar materials and can be applied either to the entire surface or only to specific areas that are particularly sensitive to adhesion. A number of problems can be avoided by applying non-stick coatings to rotary dies:

- Deterioration of the die-cutting result due to material deposits

- Increased wear of the die-cutting tools (due to friction)

- Delays due to machine downtime

Wink offers three non-stick coatings for different uses:

| Description: | Excellent non-stick properties for medium to large runs. Successfully used for various industrial applications, especially in the automotive sector. |

| Non-stick effect: | +++++ |

| Run size: | ++++ |

| Food safe: | no |

| Description: | Premium quality for high demands and long service life. Preferred applications are medical/hygiene, food and other industrial applications. |

| Non-stick effect: | ++++ |

| Run size: | ++++ |

| Food safe: | yes |

| Description: | Transparent premium variant with excellent non-stick effect. Suited to cut into uncovered adhesive. |

| Non-stick effect: | +++++ |

| Run size: | +++++ |

| Food safe: | yes |

Clean die-cutting tools

Flawless die-cutting results

Time-saving due to less cleaning effort

Longer running life

Food safe

- Three different Non-Stick coatings for different applications: Grey SLC, Black PTFE, Clear SHP

- Food safe: Black PTFE & Clear SHP

The right contact

Would you like to request an offer or place an order? Do you have general or technical questions? Our friendly and competent team will answer all your questions about our products and our service.