SmartGap®

Simply smart

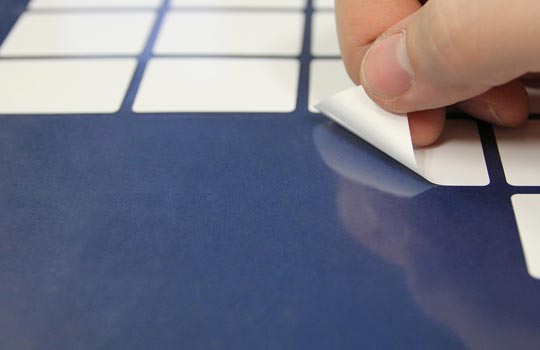

Whether ultra-thin substrates, through-cuttings, large working widths or high production speeds: With the adjustable anvil SmartGap® you can easily achieve perfect die-cutting results.

Why adjustable?

The variety of materials and ever thinner liners place special demands on all die-cutting components. Adjustable anvil cylinders allow variable adjustment of the gap dimension and thus the cutting depth. In many cases, however, conventional adjustable systems struggle with problems - especially with cutting-through, large working widths and high production speeds.

Wink‘s SmartGap® system overcomes these limitations. The SmartGap® enables you to flexibly and accurately adjust the cutting depth to your needs. The system convinces with a highly precise gap adjustment on both sides and a particularly stable construction, which ensures unique running smoothness.

SmartGap® versions

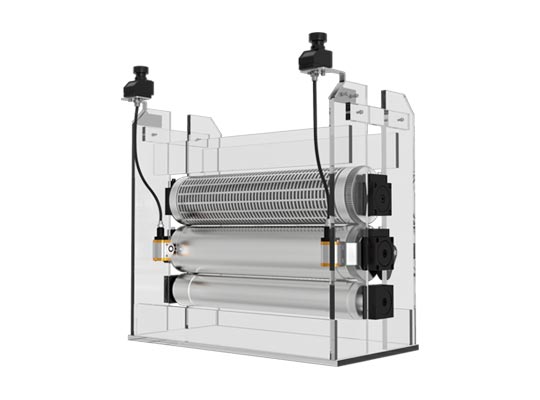

All SmartGap® versions use the same proven stable design, with the extra wide bearing rings of the support roller backing the body of the anvil cylinder. While the basic ADVANCE version is controlled purely mechanically using adjustment knobs, the TOUCH digital version is controlled via a control unit and display.

The Touch model provides a number of powerful functions that make die-cutting more efficient than ever. The basic Advance version can be easily upgraded to the digital Touch version, which can be extended with an AutoControl package. No matter which version you choose, with the SmartGap® you are perfectly equipped for the future of rotary die-cutting.

SmartGap® benefits at a glance

Leading printers and press manufacturers worldwide rely on the SmartGap® system, which sets new standards in terms of functionality, stability and efficiency.

Perfect die-cutting results and maximum productivity

- high-precision adjustment of the cutting depth on both sides

- trouble-free processing of challenging materials and thin liners

- avoidance of complaints

- comfortable and user-friendly handling

- digital extensions for optimized workflow and automated die-cutting

Die-cutting without limitations

- no restrictions as with other adjustable systems

- unique running smoothness even with a high proportion of transversal lines

- high machine speeds possible

- suitable for larger working width

- flawless cutting-through/perforating

Maximum efficiency

- less waste and material consumption

- shorter set-up times and reduced machine downtimes

- longer service life of all cutting components (flexible dies, cylinders, bearer rings

- special construction prevents excessive heat development

- system for easy gap adjustment, consisting of adjustable anvil cylinder and a support roller, both solid and hardened. The digital version includes a touch display and a control unit.

- adjustment range ± 80 microns

- individual adjustment on both sides, at standstill and when machine is running

- construction possible for all common machine types and working widths

- suitable for cutting from below

| Basic functions: | Advance | Touch | AutoControl |

| Technical basis: | Through-hardened anvil cylinder with high-precision eccentric adjustment unit and special support roll for maximum stability | ||

| Adjustment range: | ± 80 microns | ||

| Minimum adjustment steps: | 0.5 microns | standard: 0.5 microns; optionally down to 0.1 microns | |

| Operation/control | analog (rotary knobs) | digital (touch screen) | |

| display | only gap value | Gap value (metric or imperial), controls and additional information | |

| Gap adjustment left/right individually | yes | yes | yes |

| Gap adjustment left/right simultaneously | no | yes | yes |

| Product information, care instructions, cutting tips | no | yes | yes |

| Network connection | no | yes | yes |

| Monitoring of web and die-cutting result | no | no | yes |

| Automatic adjustment of gap dimension | no | no | yes |

The right contact

Would you like to request an offer or place an order? Do you have general or technical questions? Our friendly and competent team will answer all your questions about our products and our service.