SmartGap® Advance

As the basic model in the SmartGap® range, the ADVANCE already meets the highest demands in the production of labels and other narrow web products. Thanks to its unique stability, you can easily achieve perfect die-cutting results even at high speeds. To further increase efficiency, you can easily upgrade the Advance to the digital versions TOUCH and AUTOCONTROL.

The solid basis for your die-cutting success

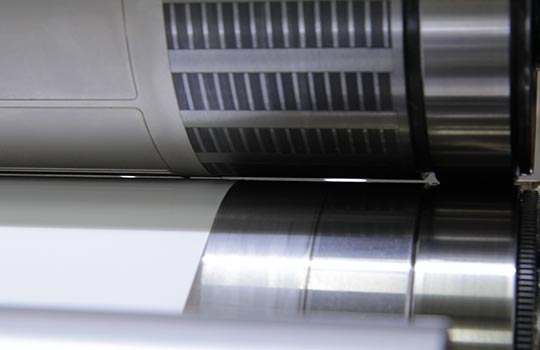

The gap between the magnetic cylinder and the anvil cylinder, also known as “clearance“ or “undercut“, is of particular importance during die-cutting. In combina-tion with the thickness and composition of the liner material, the gap dimension determines the opti-mum height of the flexible die.Changes in the gap size (e.g. due to wear or heating) have a negative effect on the cutting result. More-over, there are further challenges in die-cutting: tool tolerances, fluctuating liner gauges and ever thinner liners. With the adjustable SmartGap® system, you have the cutting process under control at all times. A high-precision eccentric mechanism quickly and precisely regulates the gap (and therefore the cutting depth).

Easy handling - maximum precision

Using two rotary knobs on the unit frame, you can individu-ally adjust the gap on both sides to compensate for one-sided wear, inaccuracies in the cutting tool and fluctuations in material thickness.If the knob is turned in the “GAP +“ direction, the gap size is reduced and thus the cutting becomes deeper. Turning the knob in the “GAP -“ direction reduces the cutting depth by increasing the distance between the cylinders. Adjustment is possible both at standstill and while the machine is running. The adjustment steps are only half a micron, so that even the smallest corrections can be made.

Maximum precision

High-speed production

easy operating

Low maintenance

Control unit flexibly positionable

- system for easy gap adjustment, consisting of adjustable anvil cylinder and a support roller, both solid and hardened. The digital version includes a touch display and a control unit.

- adjustment range ± 80 microns

- individual adjustment on both sides, at standstill and when machine is running

- construction possible for all common machine types and working widths

- suitable for cutting from below

- SmartGap® cylinder

- adjustment knobs

- adjustment units

- support roller

The right contact

Would you like to request an offer or place an order? Do you have general or technical questions? Our friendly and competent team will answer all your questions about our products and our service.