Flexible dies for sheet-fed printing

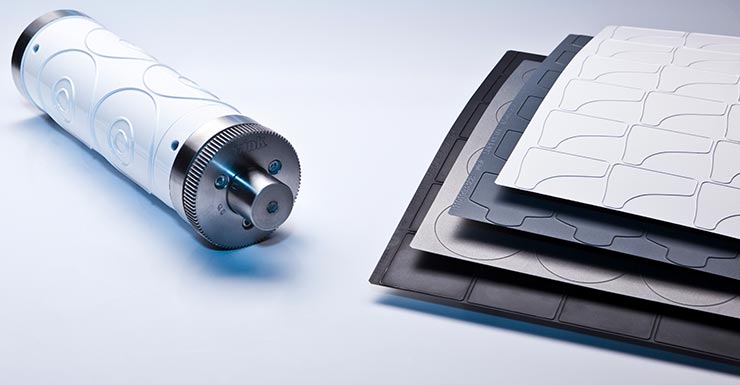

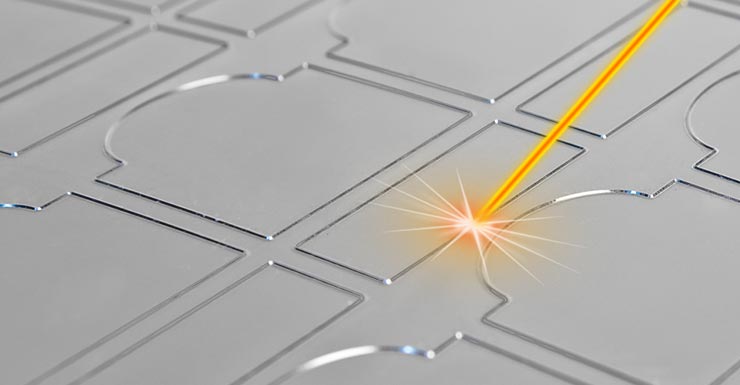

Whether sticker sheets, presentation folders or inmould labels: our flexible dies can be used in almost all machines for any print format - simply, quickly and with maximum precision. The innovative technology ensures efficient inline production for kiss-cutting, through-cutting, perforating and creasing.

Sheet-fed offset

For inline die-cutting in sheet-fed offset presses, the flexible die is mounted in a free printing or coating unit instead of the blanket. The clamping system can be either quick clamping rails, adapter rails or a grooved gripper edge (for clamping in conventional rails). The impression cylinder is protected with a special protector plate. Our plates are successfully used in the sheet-fed offset machines of all well-known manufacturers, e.g:

- Heidelberg

- Koenig & Bauer

- Manroland

- Komori

- Ryobi

- Sakurai

Short set-up times

Maximum precision

Perfect die-cutting results

Easy mounting

Repeat accuracy

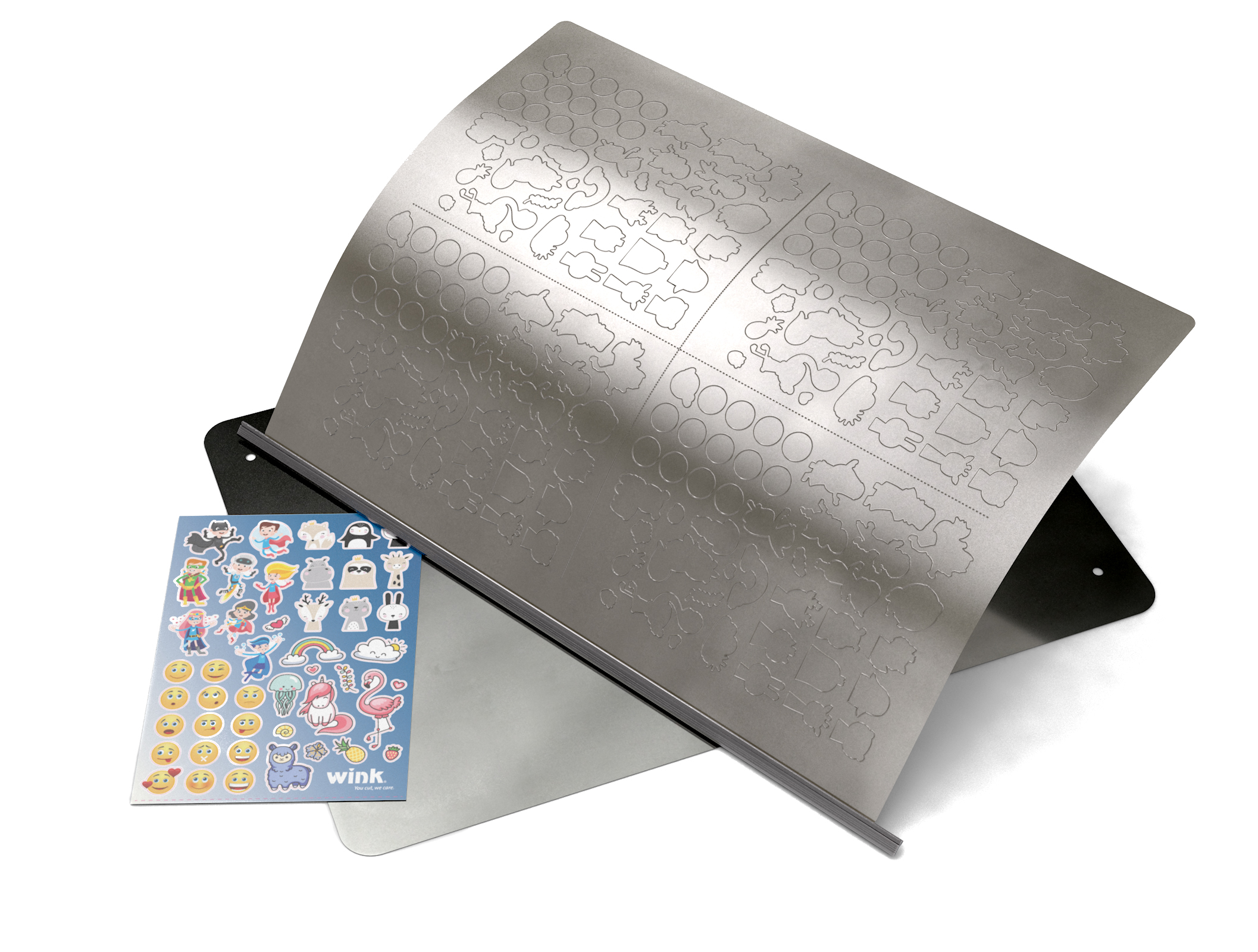

Inmould-Labels (IML)

Rotary die-cutting of inmould labels allows higher process speeds and many other advantages - inline and offline. In new applications, even the smallest circular elements (injection holes) can be accurately die-cut and vacuumed. With minimal production tolerances and special cutting line geometries, the high-precision die-cutting tools from Wink offer optimum conditions for die-cutting inmould labels with maximum efficiency. Typical machines on which our flexible dies are used worldwide are the Koenig & Bauer RDC 106 and the Heidelberg XL 105/106 (DD). A problem-free integration of our tools is also possible for other sheet-fed offset or die-cutting machines.

DIGITAL FINISHING

Finishing machines such as those offered by Bograma, Horizon or Rollem are often used for shorter runs in the digital printing sector. With little effort, these die-cutting systems can process a wide variety of printed materials, e.g. inserts, presentation folders, folding boxes, business cards, labels and products in the pharmaceutical/cosmetics sector. The die-cutting and perforating applications can be combined on one flexible die. For additional creasing applications a pair of tools is used. Due to the easy application with highest register accuracy, set-up times are considerably shorter and production costs are optimized.

VERSIONS:

- SuperCut 70, SuperCut 90, SuperCut Special

- Tolerance: ± 0,002 mm

- Finishings: MC coating, MCR coating, Non-Stick coating, laser hardening

SIZES AND HEIGHTS

- Paper and carton materials, maximum 0,4 mm thickness of printing substrate

- Die height depending on material (max. 1,5 mm)

- Up to printing format 3b

CLAMPING SYSTEMS

- Quick release clamps for printing and varnish units

- Adaptor clamps (instead of conventional bars)

- Corrugated gripper with Bacher cuttings on flexible dies (to install into convential bars)

PROTECTION OF ANVIL CYLINDER

- For cutting-through the anvil cylinder should be protected by a wisp® protection plate

- Usually the Wink protection plates adhere also well to roughened anvil cylinders; however, this should always be checked and ensured in advance.

PROTECTION PLATES

- Standard sizes: 700 x 1.000 / 500 x 700 / 350 x 500 mm

- Maximum size: 740 x 1.040 mm

- Die height without adhesive tape: 0,20 mm

- Die height including adhesive tape: 0,32 mm

- Rust protection (included)

- Laser hardening (optional)

- Non-Stick coating (optional)

The right contact

Would you like to request an offer or place an order? Do you have general or technical questions? Our friendly and competent team will answer all your questions about our products and our service.