Non-Stick coatings

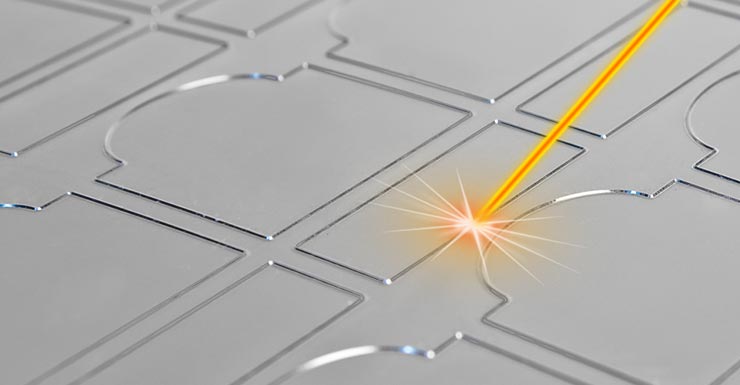

Wink Non-Stick coatings for flexible dies minimise adhesive and ink residues on the cutting edge and die surface, ensuring an uninterrupted manufacturing process. The flexibility and magnetic adhesion of our dies are not at all impaired by our Non-Stick coatings.

Versions

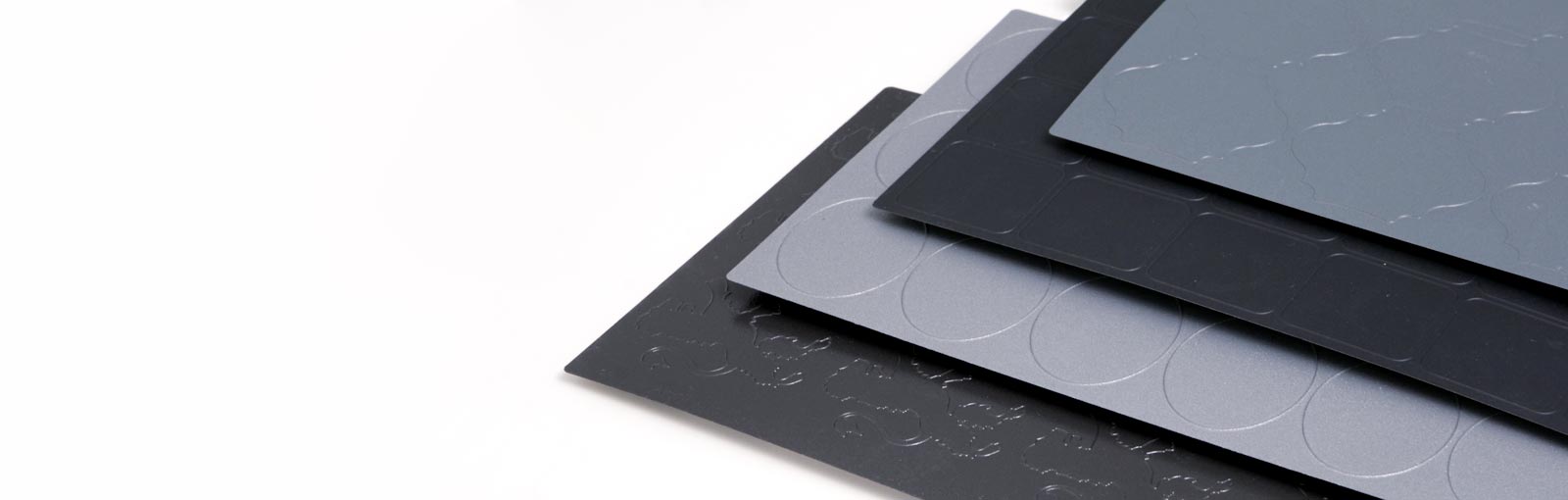

We offer you four different Non-Stick coatings, which are optimised for specific applications. It is also possible to apply our Non-Stick coating on equipment (e.g. ink trays, guiderollers). For rotary dies we offer these coatings.

| Recommendation: | Standard labels |

| Anti-adhesive strength: | +++ |

| Anti-ink strength: | - |

| Production time: | 24h |

| Recommendation: | Standard and multilayer labels, hotmelt adhesives |

| Anti-adhesive strength: | +++++ |

| Anti-ink strength: | + |

| Production time: | 24h |

| Recommendation: | Multilayer labels, hotmelt adhesives |

| Anti-adhesive strength: | ++++++ |

| Anti-ink strength: | +++ |

| Production time: | 48h |

| Recommendation: | Protection plates, guide rollers |

| Anti-adhesive strength | ++ |

| Anti-ink strength: | ++++ |

| Production time: | 24h |

Clean die-cutting tools

Flawless die-cutting results

Time-saving due to less cleaning effort

Longer running life

Combinable with other finishes

Notice

Important information for the use of dies with Non-Stick coating: Flexible dies with Non-Stick coating require a “running in” phase whereby the Non-Stick coating is removed from the tip of the cutting edge. During this “running in” phase the cutting/stripping result may not be perfect, but this is only temporary. After this process completely normal operation of the flexible die is assured.

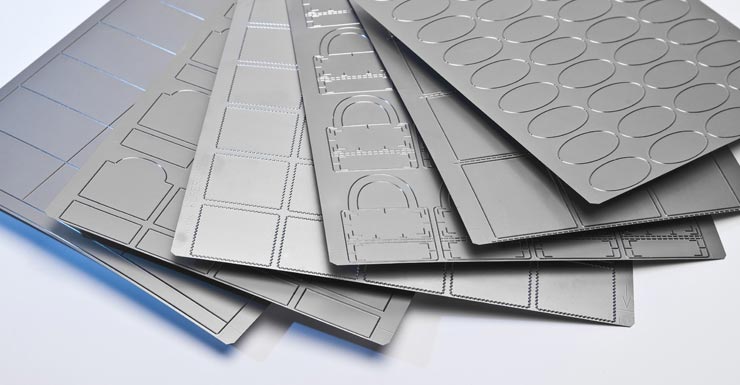

- Four different Non-Stick coatings for different applications: Grey, Grey Premium, Black, Silver

- Magnetic adhesion is fully preserved

- Also suitable for solid dies and accessories

The right contact

Would you like to request an offer or place an order? Do you have general or technical questions? Our friendly and competent team will answer all your questions about our products and our service.