PowerCut®

solid dies

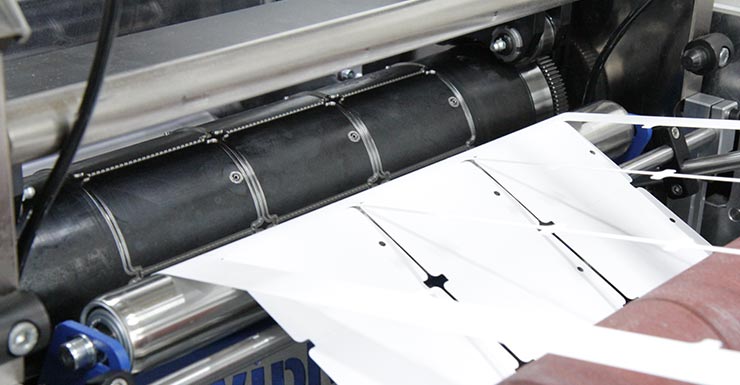

Our PowerCut® solid dies impress with their precision and durability. Each cylinder is manufactured using the latest CNC technology and adapted exactly to your individual requirements.

Maximum power

For many applications in narrow web printing, solid rotary dies continue to be the first choice, e.g. for cutting very thick labels, cardboard packaging and non-woven fabrics. Our PowerCut® cylinders are convincing because of their precision and long life. Each cylinder is manufactured using the latest CNC technology and adapted precisely to your individual requirements.

Contact us!

Wink competence center cylinders

Dimensions

- PowerCut® cylinders are hardened on principle and can be repeatedly reworked and resharpened

- all common working widths and diameters are available, special sizes on request

- standard hight of cutting lines is 1.2 mm, of course other heights and several cutting depths on one cylinder are also no problem

- for easy waste removal we offer solid dies with spring ejectors (PinEject) and versions for blowing/suction (AirTec/VacTec)

- the D3 version is made from tool steel and is well suited for kiss-cutting of standard papers and films and smaller runs

- made from high-quality tool steel, the D3+ variant comes with a significantly increased lifetime, especially suited for kiss-cutting and cutting-through in long runs

- the D4 version made of special tool steel meets the highest standards and is the ideal choice for very long runs and particularly abrasive materials (e.g. thick PVC or metal foils)

- Our Pro coating against wear significantly increases tool life. In addition, we also offer other special coatings, which are adapted to particular customer requirements. If desired, all PowerCut® cylinders are available with non-stick coating, which provides highly effective protection against ink and adhesive residues and thus makes for a smooth production process.

The right contact

Would you like to request an offer or place an order? Do you have general or technical questions? Our friendly and competent team will answer all your questions about our products and our service.